GP Crystalline Active Barrier (CAB) FLEX 2C

GP® Crystalline Active Barrier (CAB) Flex 2C is a two component, fast drying grey waterproofing coating system. The A component is a cement-based powder and B component is a liquid polymer. Due to the polymer the coating system is semi flexible.

Read MoreProduct Benefits

- Dry mortar

- EN 1504-3 – Class 3 repair mortar barrier

- Watertight against pressurized water (50 bar, depend on surface)

- Frost resistant

- High compressive strength

- Capillary blocking

- Low consumption

- Easy application

- Sprayable

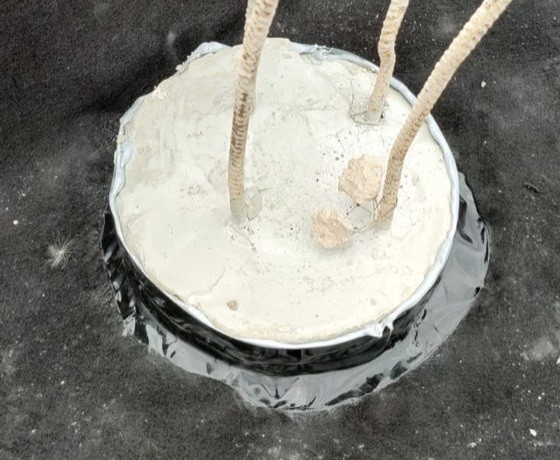

- Suitable as Pile head/Cap sealing

Two component cementitious/polymer sealing slurry – (Fast drying, hydrophobic, waterproof).

GP® Crystalline Active Barrier (CAB) Flex 2C is a two component, fast drying grey waterproofing coating system. The A component is a cement-based powder and B component is a liquid polymer. Due to the polymer the coating system is semi flexible. CAB Flex 2C migrates into the substrate and seals the pores of the substrate to achieve excellent bonding to the surface. It is shrinkage compensated and has quick strength development. CAB Flex 2C also has very good abrasion resistance on the substrate.

| Characteristics | GP® Crystalline Active Barrier (CAB) Flex 2C |

|---|---|

| Base component A | Cement, quartz sand, additives |

| Base component B | Rubber dispersion, additives |

| Colour | Grey |

| Processing temperature | + 5°C up to + 35°C |

| Bulk density component A | Approx.1.6 g/cm³ |

| Density component B | Approx. 1,01 g/ml Page 2 |

| Characteristics | GP® Crystalline Active Barrier (CAB) Flex 2C |

|---|---|

| Water vapour diffusion resistance factor μ | Approx. 65 |

| Trafficable | After approx. 4-6 hours |

| Loadable | After approx. 3 days |

| Applicable | Approx. 45 minutes at 20°C/50% rel. h. |

| Curing time | After approx. 48 hours |

| Complete curing | After 28 days |

| Shrinkage | <0.02% |

| Consumption | 2.0mm approx. 3 - 3.5 kg/m² |

| 2.5mm approx. 3.5 - 5 kg/m² | |

| Minimum thickness | Approx. 2 mm where no pressurised water |

| Approx. 2.5 mm where anticipating pressurised water | |

| Compressive strength | Class R3 (>25 MPa) |

| Chloride ion content | < 0.05 % |

| Adhesive bond | > 1.0 MPa |

| Elastic modulus | > 10 GPa |

| Capillary absorption | ≤ 0.5 kg/m² × h 0.5 |

| Reaction to fire | Class A1 |

CAB Flex 2C is used for reliable and permanent waterproofing against pressurised water on positive side (outside) as well as on negative side (inside) of buildings. CAB Flex 2C can be used on vertical and on horizontal surfaces to be waterproofed. It is applicable on nearly all mineral sufficiently solid surfaces with an ideal strength of >1.5 N/mm². Typical application areas are basements, concrete elements, car parking, tunnels, water tanks, wet rooms, or manholes. CAB Flex 2C is also usable as waterproofing under walls, and across pile heads/caps against rising dampness.

Surface Preparation

The surface must be dry or slightly damp, sound, absorbent and clean. Bonding inhibiting agents such as grease, oil, formwork oil and all loose particles and dust must be removed before application of CAB Flex 2C.

Damaged area like cracks, holes or cavities must be reprofiled. Cavities or surface damages >5mm must be reprofiled. The pores of substrate must be open, so CAB Flex 2C can penetrate.

Dusty or salt damaged surface must be treated with Deep Primer prior application of the slurry so the substrate is re-solidified and salts are transferred from soluble to insoluble and during curing time of the slurry no salts can penetrate into the CAB Flex 2C during curing.

Negative / Positive side waterproofing

CAB Flex 2C must be mixed with using of a slow speed mixer in the designed mixing ration (25 kg by 8 kg). Put component B (please shake it before using) in a mixer (or container provided) and add the whole bag of sealing slurry (component A), mix it until a lump-free compound is attained. After mixing wait 1 minute and mix again. The application on the surface must be done with a hard brush or spraying device. The coating in principle is done by minimum 2 layers, whereby the minimum thickness has to be observed. The first layer must not be completely cured before the second layer is applied or the surface has to be prewetted.

The whole system has to be secured against over fast drying (wind, sun etc.), frost and rain. At negative side waterproofing the rel. air humidity should not be higher than 65%. CAB Flex 2C can be covered with coating for water vapor diffusion or plasters.

Recommended tools:

- Roller

- Gloves

- Safety glasses

- Mixer

- Spraying device

For spray application: use traditional wet mortar spraying equipment and processes.

33 kg units (25 kg comp. A + 8 kg comp. B).

6 months (frost-free and dry, +5°C up to +25°C in original packaging).

BBA Certificate 20/5728

Juta Solutions & Applications

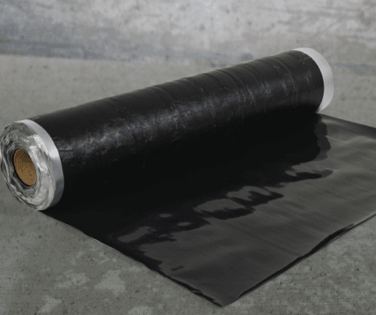

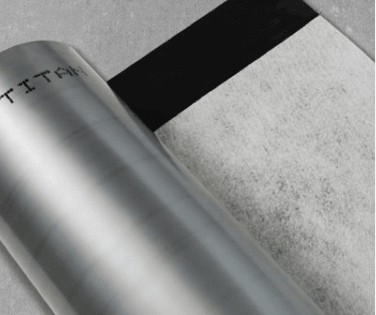

Our waterproofing membranes and structures suit a variety of applications and situations, with our TITAN® range offering not only superior waterproofing qualities but also offering invasive weed control and gas protection.

Get In Touch With The Experts

If you feel first class service, premium products direct from source, and bespoke solutions are right for you then don't hesitate to contact our team today on 01772 754177 or email us at [email protected]

Contact Us