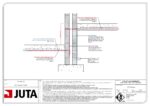

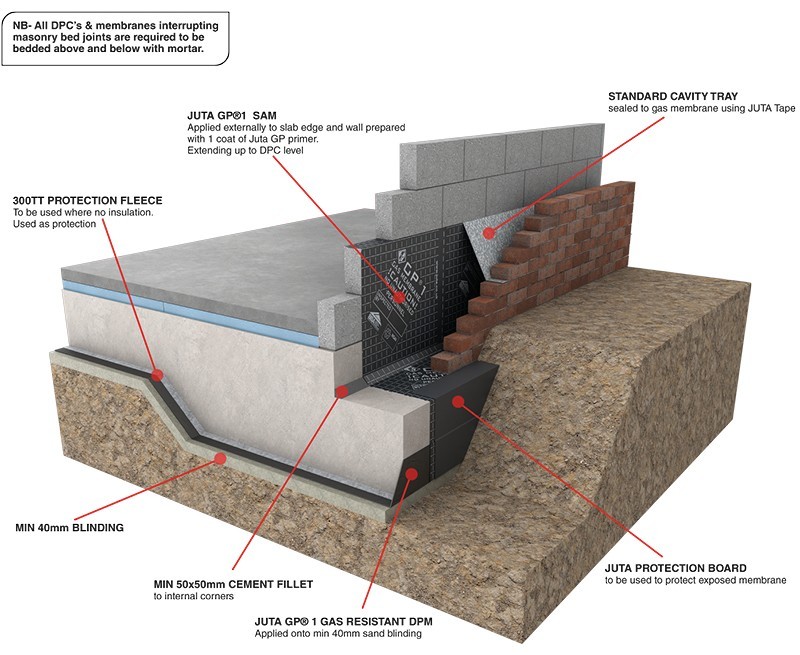

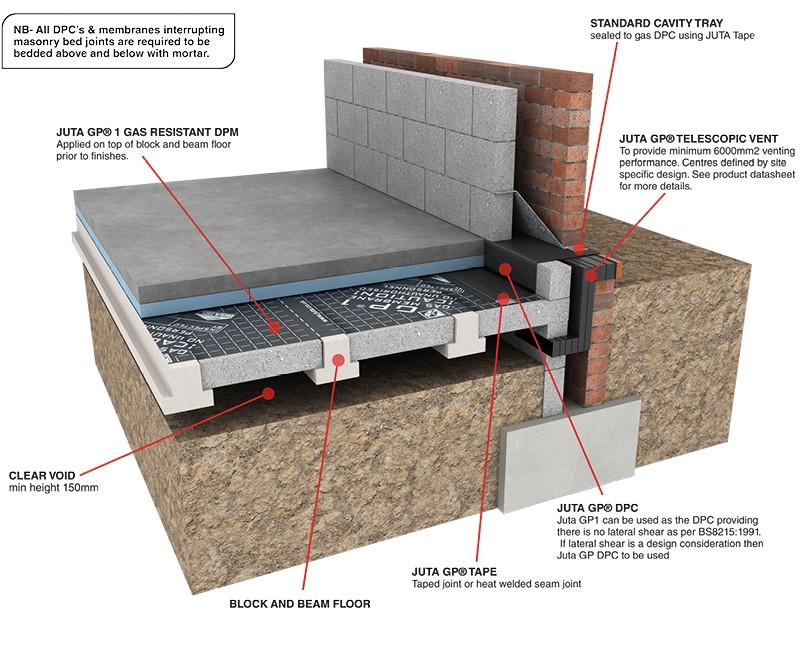

BS 8485:2015+A1:2019 – Codes of practice for the design of protective measures for methane and carbon dioxide ground gases for new buildings.

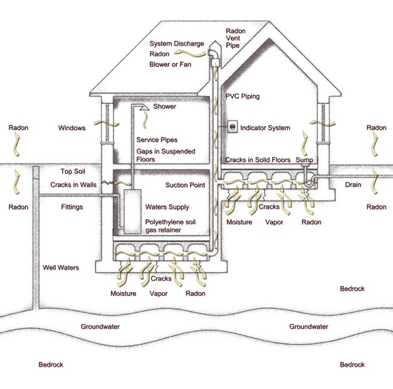

- Ground gases typically found near landfill sites, but can occur from other sources

- Encourages the use of qualified installers

- Validation to Ciria C735 is a requirement

- Additional influences on the system should be considered, such as the hydrostatic conditions, and the likelihood of the source contaminant being in direct contact with the protective measures proposed

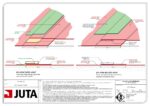

BRE 211:2015 – Guidance on protective measures for new buildings. (RADON)

- Naturally occurring ground gas. Larger concentrations in the South-West of UK

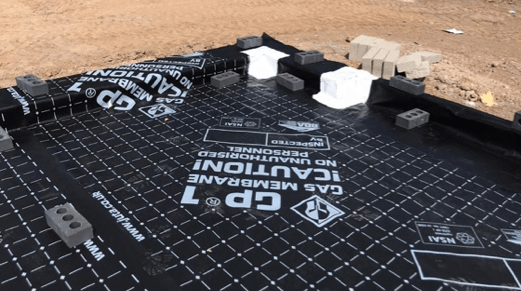

- Minimum recommendation is a membrane of 300 micrometre (1200 gauge) polyethylene sheet or equivalent

- It must be installed with considerable care and protected once installed

- Taped laps are required

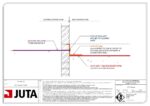

CIRIA C748:2014 – Guidance on the use of plastic membranes as VOC vapour barriers

CIRIA C682:2009 – VOC Handbook

- Risk based approach

- No quantifiable limits on material performance

- Testing to ISO 15105-2 and EN 14414/EN 14415

- 9 main VOC types are tested for

- Welded laps are required as most tapes are made from bitumen/butyl and are affected by VOCs

CIRIA C735:2014 – Good practice on testing and verification of protection systems to buildings from hazardous gases

- Good practice on testing and verification of protection systems to buildings from hazardous gases

- Check design and detailing is in accordance with site requirements

- Checks the competency of the installer (NVQ LEVEL 2 minimum)

- Test integrity of the membrane/barrier system

- Visual inspection

- Written report on inspection/testing and sign-off

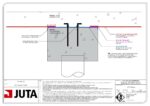

BS8102:2009 – Code of practice for protection of below ground structures against water from the ground