Croatian Waste Treatment

Ensuring environment is not contaminated with seepage water

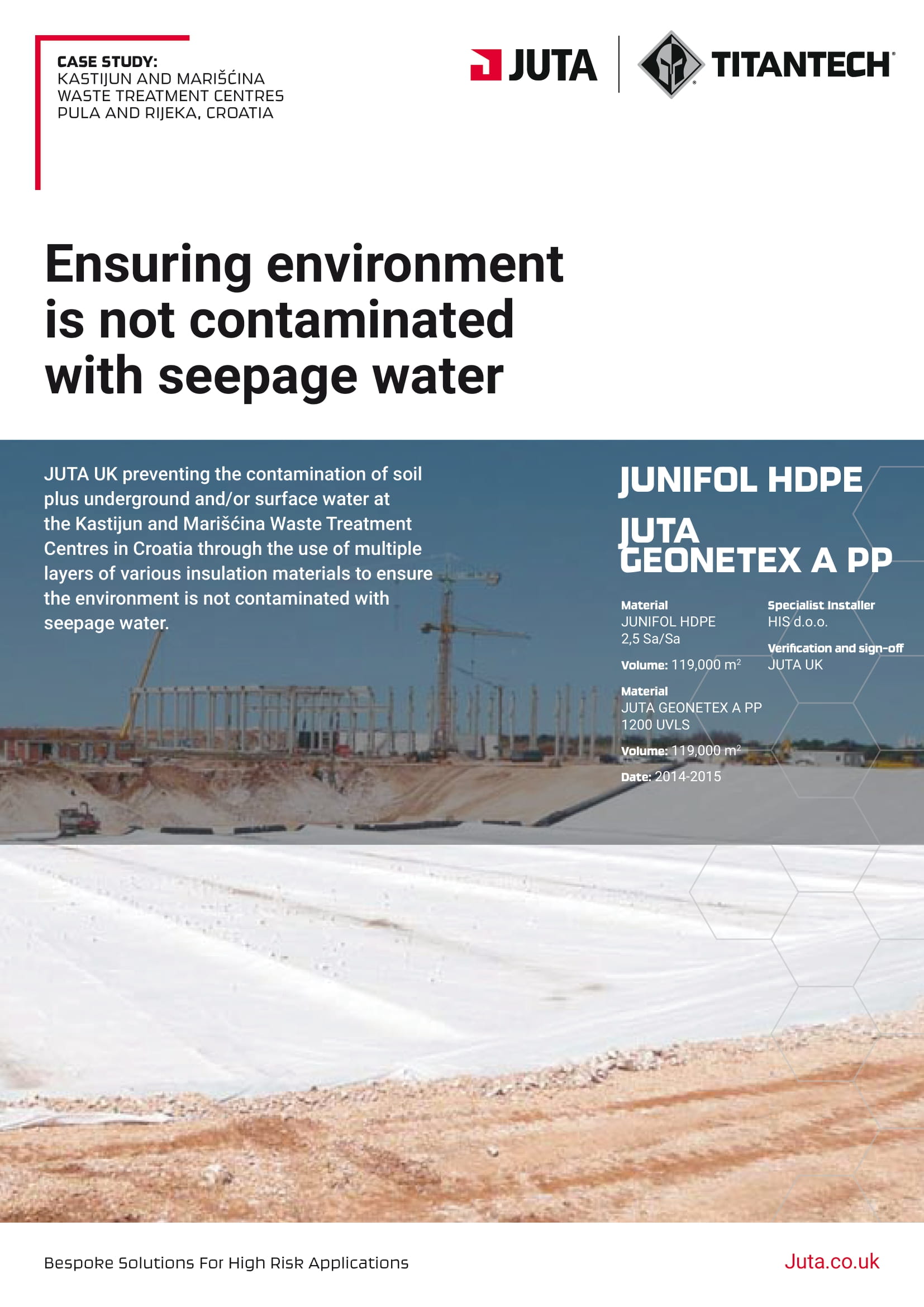

JUTA UK preventing the contamination of soil plus underground and/or surface water at the Kastijun and Marišćina Waste Treatment Centres in Croatia through the use of multiple layers of various insulation materials to ensure the environment is not contaminated with seepage water.

-

Material:

HDPE 0.6 MMVolume:

119,000 m2 -

Material:

JUTA 300TTVolume:

119,000 m2 -

Date:

2014 - 2015 -

Specialist Installer:

HIS d.o.o. -

Verification and sign-off:

JUTA UK

The individual administrative regions of Croatia are supposed to accommodate their waste management system to the respective requirements of EU till 2018. The centres Kastijun and Marišćina represent reference projects built to serve the districts of Istria (population abt. 200,000, the district town Pazin) and Primorsko-goranska (population abt. 300,000, the district town Rijeka).

Both projects were designed and implemented with an emphasis on environmental friendliness and the use of the most up-to-date waste management methods. Both centres comprise several different sections (mechanical-biological waste treatment, stabilised waste dump, disposal site for the other types of waste, seepage water reservoirs, retention basins, cogeneration unit, etc.) and all the waste collected in these areas should be processed here. Possible future extension of the capacity of the individual disposal sites (to provide more space for waste that cannot be utilized further) has also been anticipated.

According to the respective EU directive, all waste disposal sites must be located and designed in a manner preventing the contamination of soil plus underground and/or surface water. Both during the landfill’s active and passive (after the site has been closed) stages, it is essential to ensure that the environment is not contaminated with seepage water.

This requirement is usually accomplished using an insulation multilayer, the most frequently used method being the combination of natural geological barrier and a man-made insulation layer.

Moreover, in the case of Marišćina waste treatment centre, a geomembrane leak detection system was installed. Both centres have been operational since 2015.

For the disposal sites of the mentioned waste treatment projects, the following multiple layers of various insulation materials were used:

- Filtration layer of sand 0.25 m

- Separation + filtration non-woven geotextile 300 g/m2

- Drainage + protective layer of aggregate 0.5 mm

- Protective non-woven geotextile JUTA geoNETEX A PP 1200 g/m2 JUNIFOL HDPE geomembrane, thickness 2.5 mm

- Bentonite mat 5 kg/m The subbase material 0.5 m