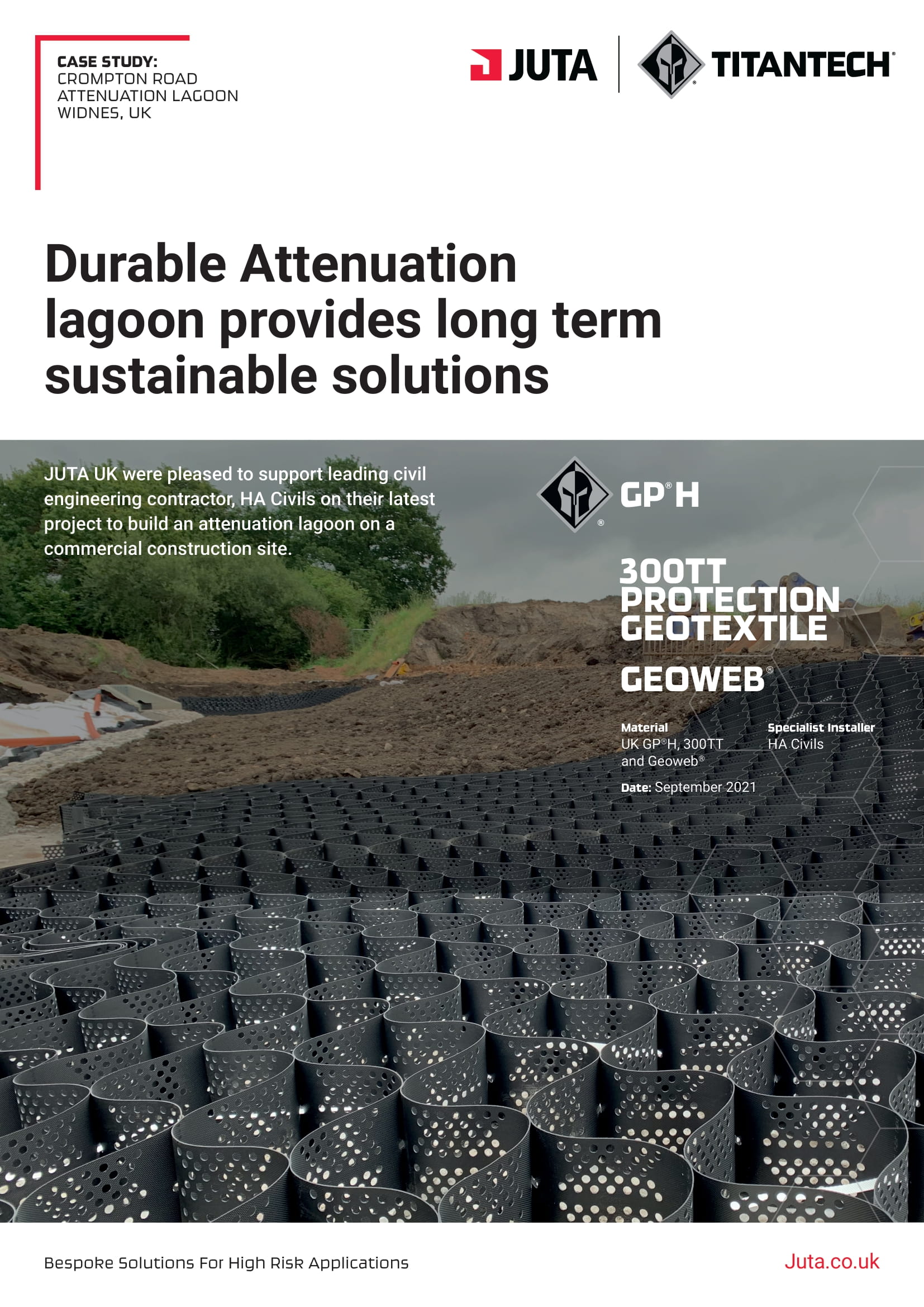

Crompton Road Attenuation Lagoon

Durable Attenuation lagoon provides long term sustainable solutions

JUTA UK were pleased to support leading civil engineering contractor, HA Civils on their latest project to build an attenuation lagoon on a commercial construction site.

Products used:

GP®H, 300TT PROTECTION GEOTEXTILE, GEOWEB®

-

Material:

GP®H, 300TT PROTECTION GEOTEXTILE, GEOWEB® -

Date:

September 2021 -

Specialist Installer:

HA Civils

Attenuation lagoons help to control stormwater runoff and are considered the most effective temporary method for storing excess water on site.

From design right through to implementation JUTA UK partnered with local suppliers to specify and install an effective attenuation system at the former Golden Triangle industrial estate in Halebank, Widnes.

The former 20-acre industrial estate is being redeveloped by Halton Council to make way for 360 new homes and commercial units. The design and implementation of the land to form a pond for site works, was the first phase of a wider £60M scheme.

The SUDS manual (C753) was used as the basis for design, which ensured correct material specifications. All too often, JUTA UK has witnessed unsuitable damp proofing membranes taped together and covered with basic separation geotextiles, which over time leads the system to fail over time.

JUTA UK commented: “ From design right through to implementation the JUTA UK team partnered with the local supply chain to specify and install an effective Attenuation system that would last a lifetime.” Juta.co.uk The GP®H 0.6mm attenuation grade impermeable liner and root barrier was selected given it’s robust nature, conformance to C753, and the ability for thermal jointing (welding).

The 300TT protection geotextile was also selected as protection grade, and a class 3 filter/separator to BS8661. This ensured JUTA UK were able to offer a 50 year material warranty for the impermeable geomembrane and geotextile, which met the design life requirements of attenuation liners. A Geoweb® soil reinforcement mesh was then placed above the geotextile, and filled with site won materials to protect and maintain the impermeability of the liner. A Tendon System was employed to negate the need to anchor pins which would have resulted in damage to the liner.

The project took just one month to complete – JUTA UK partnered with local supply chain Burdens Civils, who supplied and distributed the materials for the project.

Patrick Flood, Technical Director for JUTA UK said: “All too often we see unsuitable materials used for these types of applications. The message from the government is to build back sustainably, embracing change, and improving cost driven cultures. JUTA UK achieves this by manufacturing and supplying high performance engineered materials that are designed to perform critical application functions, such as attenuation, well in excess of the service life of 50 years. The life cycle cost of our products on this scheme is less than 1p/m2”.