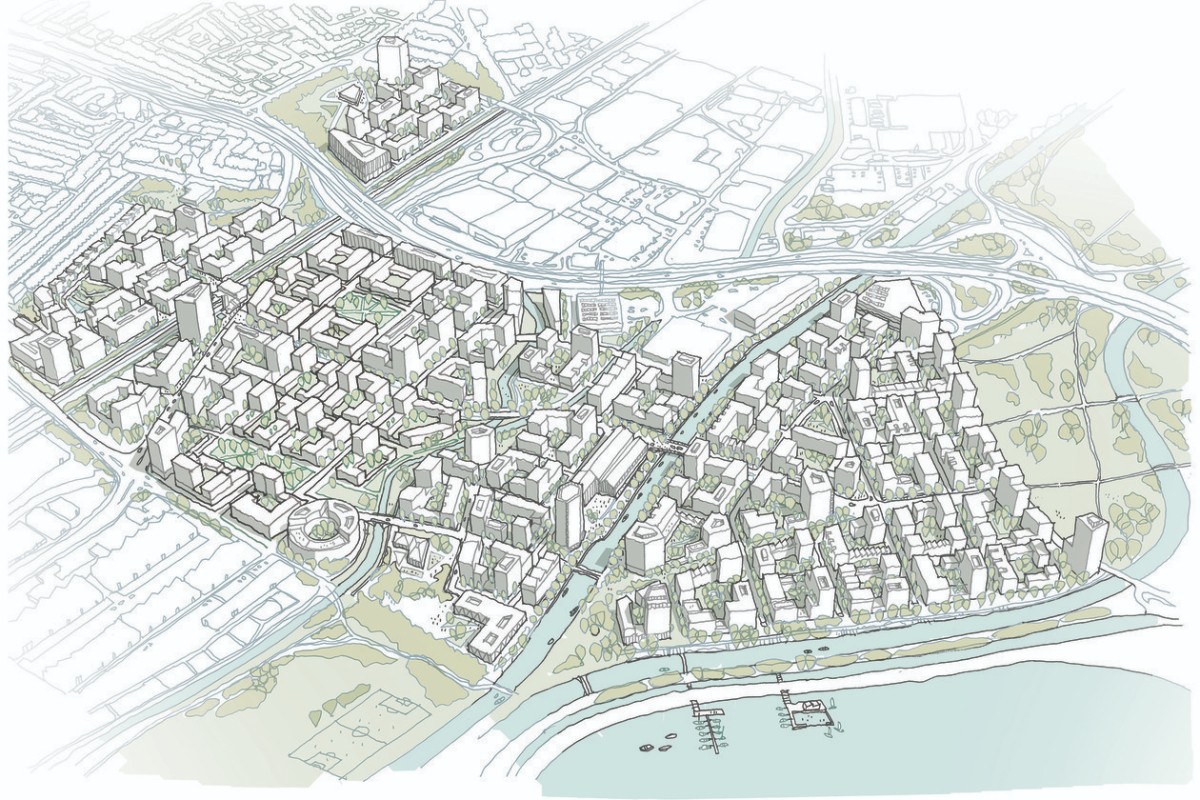

Meridian Water London

Significant UK Regeneration project gets the GP® TITANTECH® treatment

JUTA UK were delighted to support Network Rail in the first phase of development on this prestigious UK Regeneration project. Over the next 25 years the regeneration will deliver 10,000 new homes and thousands of new jobs with a Gross Development Value of £6 billion.

-

Material:

GP® TITANFLEXVolume:

22,000 m2 -

Material:

GP® TITANBONDVolume:

8,000 m2 -

Date:

2019 -

Specialist Installer:

Prestige Air Technology -

Verification and sign-off:

Membrane Testing Solutions Ltd

The development is intended to transform the economic base of the borough, creating an environment to attract a new mix of employers in the creative, professional, lowcarbon, digital, media, hi-tech and engineering sectors, with a range of large businesses alongside dedicated space and support for start-ups. All benefiting from excellent transport and Internet connections in a high quality environment.

The development is intended to transform the economic base of the borough, creating an environment to attract a new mix of employers in the creative, professional, low-carbon, digital, media, hi-tech and engineering sectors, with a range of large businesses alongside dedicated space and support for start-ups. All benefiting from excellent transport and Internet connections in a high quality environment.

To enable development a brand new Meridian Water railway station, funded and delivered by Network Rail was constructed. The first trains ran in June 2019.

The former Gas works site, falls into the previous use category, and as such the development works are treated as a Brownfield development, or regeneration. Planning conditions exist on the site, which require assessments to be made in accordance with the Environment agency guidance for contaminated land under Part 2A of the Environmental Protection Act.

As part of the risk assessment process conducted prior to development, a number of in ground contaminants were identified. The potentially harmful pollutants must be remediated or removed from the ground and/or controlled prior to development and subsequent occupation by people.

Part of the remediation process includes designing protective barrier systems into structures to prevent any residual contaminant left in the ground from entering structures and potentially being in direct contact with human receptors. This is common practice in the UK, due to our country’s small land mass, with lots of previously used brownfield land undergoing development works.

In-situ contaminants on site included a number of hydrocarbon pollutants, such as diesel and chlorinated solvents, as well as the risk of methane/carbon dioxide generation potential from made ground infill.

Andy Collins, Director at Prestige Air Technology said: “The GP® TITANTECH® family of membranes are the best performing membranes on the market. When you combine this with exceptional service from the team at JUTA UK, and the competitive price points, it’s unbeatable value.”

For more information download the PDF.