Residue Disposal Site

Providing a reliable, long-term separation of bauxite processing residue

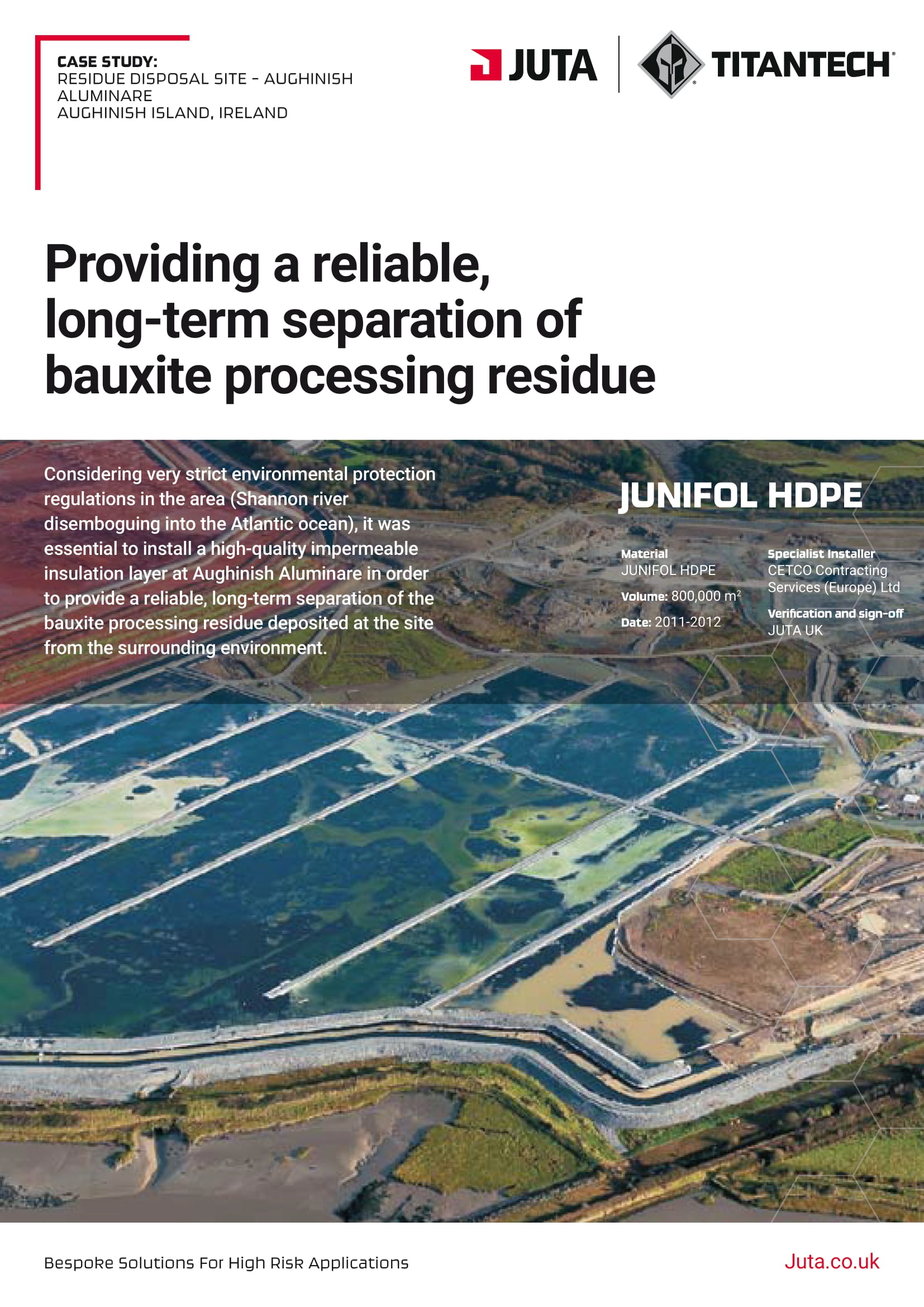

Considering very strict environmental protection regulations in the area (Shannon river disemboguing into the Atlantic ocean), it was essential to install a high-quality impermeable insulation layer at Aughinish Aluminare in order to provide a reliable, long-term separation of the bauxite processing residue deposited at the site from the surrounding environment.

Products used:

-

Material:

HDPE 0.6 MMVolume:

800,000 m2 -

Date:

2011 - 2012 -

Specialist Installer:

CETCO Contracting Services (Europe) Ltd -

Verification and sign-off:

JUTA UK

Aughinish Alumina is the largest European refinery plant manufacturing aluminium oxide (the basic raw material required for aluminium production). It is located on the South-East coast of Ireland, in the vicinity of Shannon river estuary; it was built within the period from 1978 to 1983, projected production capacity being at the level of 800 000 tons per annum.

Over the years, the volume of production has been gradually increased and nowadays, the annual output is more than 1 800 000 tons of aluminium oxide.

The compound of aluminium oxide is being obtained in a demanding manufacturing process directly from bauxite delivered to the refinery by sea transport (70 % of the processed volumes come from the Republic of Guinea in West Africa, remaining 30 % from Brasil).

After the extraction of aluminium oxide, the residue left from bauxite processing is being transferred to a sludge bed located nearby the manufacturing plant. Up to now, the originally planned storage capacity has been almost fully used up. With regards to this fact, at the present-day, extension works are being carried out at the site to acquire an additional disposal space.

Considering very strict environmental protection regulations in the area (Shannon river disemboguing into the Atlantic ocean), it is essential to install a high-quality impermeable insulation layer to provide a reliable, long-term separation of the bauxite processing residue deposited at the site from the surrounding environment.

After a lengthy and demanding tendering procedure for one of the currently largest waste disposal projects in Europe (attended by all important world ́s manufacturers of polymeric insulation materials), JUTA managed to win the tender with high-density polyethylene geomembrane JUNIFOL (thickness 1.5 mm and 2.0 mm both with a smooth and textured surface, roll width 8.0 m).