PD1700

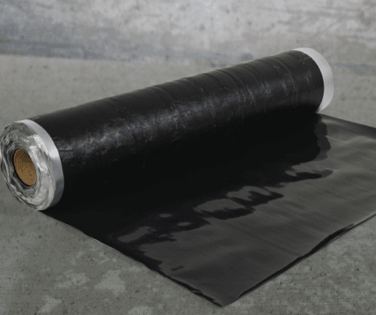

JUTA PD1700 is a high compressive strength cuspate High Density Polyethylene (HDPE) drainage core with a geotextile filter bonded to one side. Can be used in combination with GP gas or waterproofing barriers to provide both protection and drainage for external tanking applications.

Read MoreProduct Benefits

- Optimised for maximum strength and performance, providing high levels of flow.

- Complies with the latest codes of practice as published by BS, BRE and CIRIA.

- Independently tested and verified by UKAS accredited bodies.

JUTA PD1700 include a high compressive strength Cuspate High Density Polyethylene (HDPE) Drainage core with a geotextile filter geotextile bonded to one side. Protection Drainage (PD) 1700 is designed as a high flow medium to alleviate hydrostatic pressure on below ground structures, as well as providing protection to the underlying membrane (gas/waterproofing).

| Color | Black |

| Grey | |

| Material | Polyethylene |

| Shape | Rectangular - supplied in roll form |

| Size | 2 x 20 m x 8 mm |

| Warranty Description | 60 year |

| Uniclass 2015 | Pr_25_57_65_60 Plastics sheets |

| CAWS | J40/35 Loose laid plastics or rubber gas retardant damp proofing |

| J40/140 Loose laid plastics or rubber sheet gas retardant damp proofing | |

| J40/145 Loose laid weldable polyethylene gas retardant damp proofing |

| Material | High density polyethylene and geotextile fleece. |

| Purpose | Protection layer. |

| Drainage layer. | |

| Standard | To BS 8102. |

| Performance characteristics | |

| Tensile strength (minimum) | 12 kN/m. |

| Elongation to break | 12%. |

| Form | Drainage core with geotextile bonded to either side. |

| Physical properties | |

| Colour | Black and Grey. |

| Weight (minimum) | 620 g/m2 |

| Dimensions | |

| Thickness (minimum) | 8 mm. |

| Width (minimum) | 2 m. |

| Roll length (minimum) | 20 m. |

| Recycled content | 0%. |

| Country of material origin | Czechia |

| Country of product manufacture | Czechia |

| Characteristics | Test Method | PD1700 |

|---|---|---|

| CBR Puncture Resistance | EN ISO 12236 | 1700 N |

| Tensile Strength (MD/CMD) | EN ISO 10319 | 12 kN/m |

| Tensile Elongation (MD/CMD) | EN ISO 10319 | 12 % |

| Compressive Strength | EN ISO 25619 | 140 kPa |

| Characteristics | Test Method | PD1700 |

|---|---|---|

| Pore size (O90) | EN ISO 12956 | 100 μm |

| Permeability (H50) | EN ISO 11058 | 79 l/m2/s |

| In plane water flow | EN ISO 12958 | 1.83 l/s/m width i = 1.0 @ 20 kPa |

| (Hard/soft) platens | EN ISO 12958 | 1.69 l/s/m width i = 1.0 @ 100 kPa |

| (To simulate soil action) | EN ISO 12958 | 1.53 l/s/m width i = 1.0 @ 200 kPa |

| (i) Hydraulic gradient | EN ISO 12958 | 0.49 l/s/m width i = 0.1 @ 20 kPa |

| (i) = 1 simulates vertical application | EN ISO 12958 | 0.45 l/s/m width i = 0.1 @ 100 kPa |

| (i) = 0.1 simulates slope application | EN ISO 12958 | 0.45 l/s/m width i = 0.1 @ 200 kPa |

| Characteristics | Test Method | PD1700 |

|---|---|---|

| Mass per unit area | EN ISO 9864 | 620 g/m2 |

| Thickness | EN ISO 9863-1 | 8.00 mm |

| Characteristics | PD1700 |

|---|---|

| Roll Width | 2.00 m |

| Roll Length | 20 m |

| Gross roll weight | 30 kg |

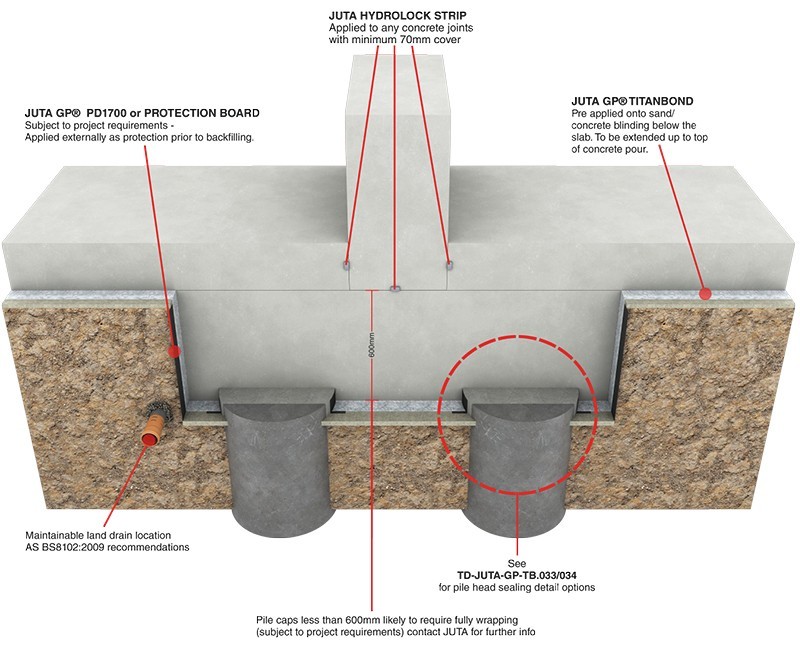

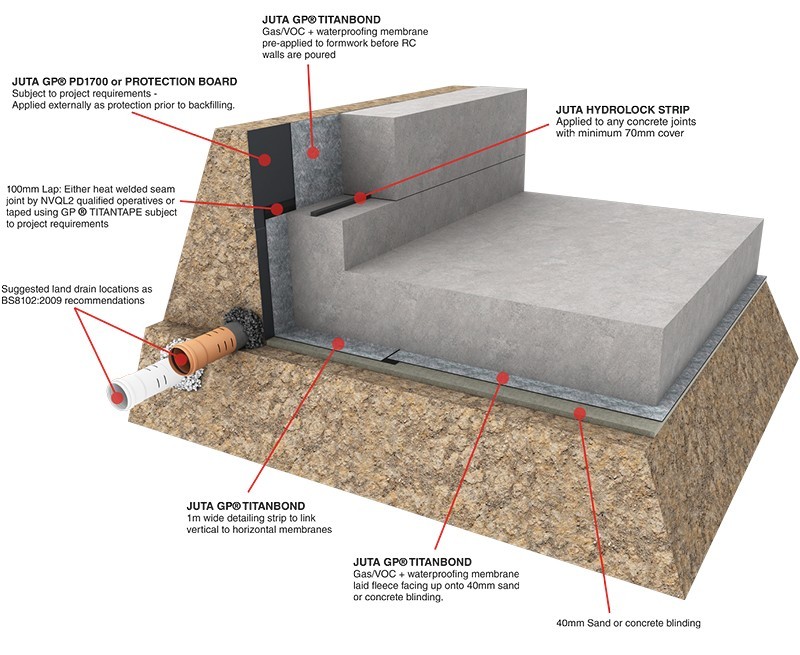

JUTA PD1700 is primarily used for external tanking applications, forming a high compressive strength void, providing a path of least resistance for water, which enables controlled drainage into outlets or connector pies. PD1700 can be used in combination with GP gas/waterproofing barriers to provide both protection and drainage for external tanking application, ensuring gas/waterproofing barrier remains intact and the system performs as intended.

Installation

PD1700 should be installed with the geotextile facing the soil/backfill, and the direction of water flow. Rolls can be cut to size on site. PD1700 can be held in place prior to backfilling with DS Butyl tape (50 mm wide), or mechanically fixed in the absence of a gas/waterproofing barrier.

Adjacent rolls can be overlapped using the geotextile, secured with DS Butyl tape (50mm). Roll ends can be connected by simply butting the cuspate sheet together.

Connection to land drains/collection pipes is achieved by placement within the slotted areas, or removal of the cuspated core and wrapping of geotextile around the pie. Care must be taken not to damage/cut the geotextile during core removal to facilitate the connection.

Backfilling should proceed with caution to avoid undue stress on the PD1700. Compactive effort should be avoided within the first 100mm of the PD1700.

Roll weights can be up to 35kg and hence appropriate equipment is required for unloading and handling. PD1700 is supplied in packaging designed to protect the product from damage during handling and storage, and degradation as a result of UV exposure. PD1700 should be kept in the supplied packaging until such time as it is required for installation, and then covered within 2 weeks of installation.

BBA Certificate 20/5728

BIM objects are digital descriptions of products or materials that, when combined with other BIM objects create a Building Information Model. These downloadable files can be used for these purposes.

Version 1 certified to 2.1

Download from NBS National BIM LibraryJuta Solutions & Applications

Our waterproofing membranes and structures suit a variety of applications and situations, with our TITAN® range offering not only superior waterproofing qualities but also offering invasive weed control and gas protection.

Get In Touch With The Experts

If you feel first class service, premium products direct from source, and bespoke solutions are right for you then don't hesitate to contact our team today on 01772 754177 or email us at [email protected]

Contact Us