Berlin Airport

Lining all in-ground filtration reservoirs with geosynthetic barriers

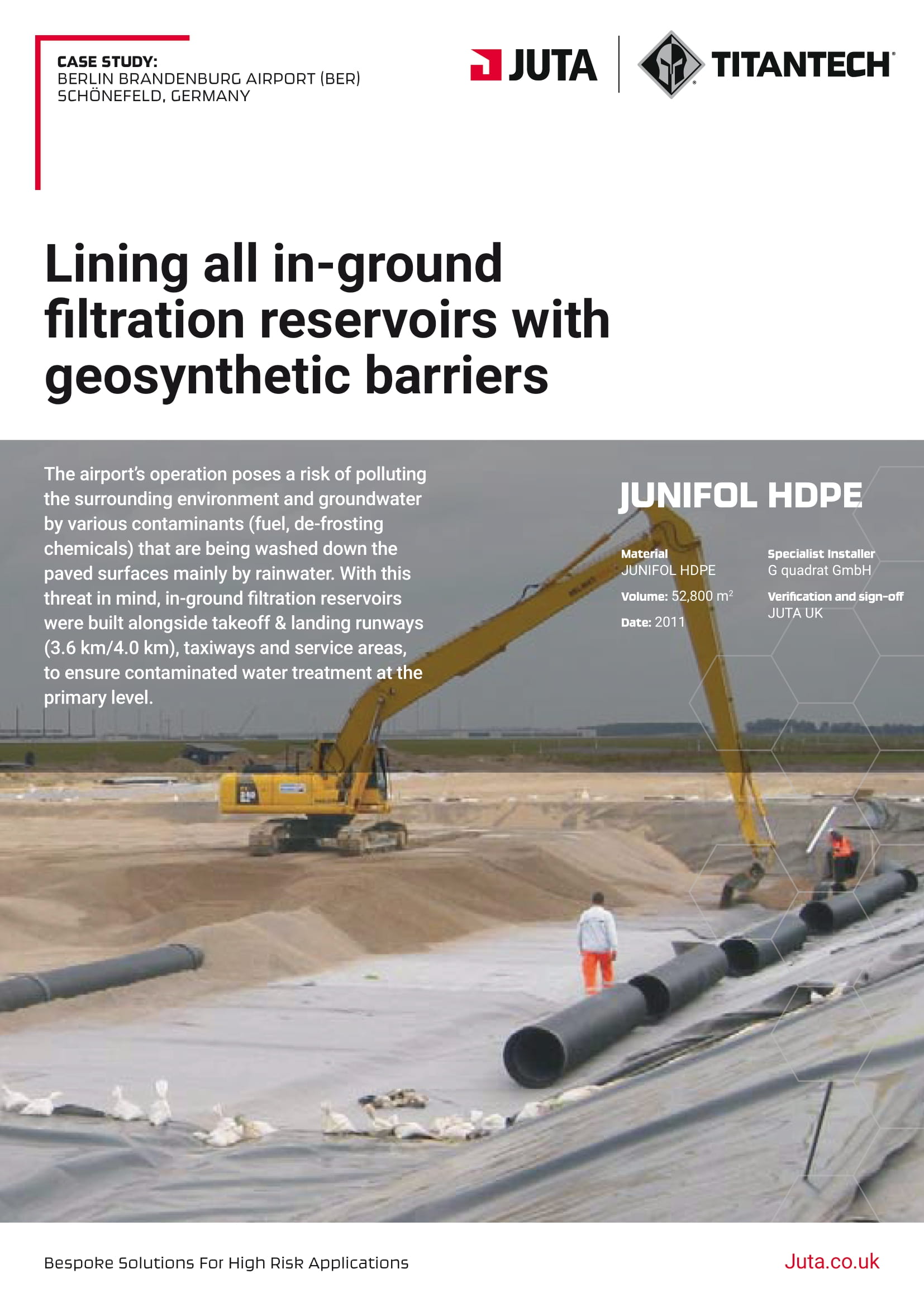

The airport’s operation poses a risk of polluting the surrounding environment and groundwater by various contaminants (fuel, de-frosting chemicals) that are being washed down the paved surfaces mainly by rainwater. With this threat in mind, in-ground filtration reservoirs were built alongside takeoff & landing runways (3.6 km/4.0 km), taxiways and service areas, to ensure contaminated water treatment at the primary level.

Products used:

-

Material:

HDPE 0.6 MMVolume:

52,800 m2 -

Date:

2011 -

Specialist Installer:

G quadrat GmbH -

Verification and sign-off:

JUTA UK

In the 1990s, the first concept of building a new large-capacity international airport near Berlin (that would aim at replacing the three existing small airports in the territory of German capital city) came into existence.

After a lengthy decision-making process, it was opted for the extension of Schönefeld airport, the only airport in the East- Berlin area that was – as opposed to the remaining two Tempelhof and Tegel airports – located outside the city limits, more concretely on the southeast outskirts of Berlin.

Construction works started in 2006 and within several following years BER project became one of the most extensive infrastructure projects in Germany. The original airport’s size of 970 ha was expanded to 1470 ha (equivalent of approximately 2000 football fields). As for the size, the target of BER is to rival the international airport in Frankfurt on the Main or Heathrow in London.

The airport’s operation poses a risk of polluting the surrounding environment and groundwater by various contaminants (fuel, de-frosting chemicals) that are being washed down the paved surfaces mainly by rainwater.

With this threat in mind, in-ground filtration reservoirs were built alongside takeoff & landing runways (3.6 km/4.0 km), taxiways and service areas, to ensure contaminated water treatment at the primary level. The secondary level treatment is being carried out in so-called central filtration reservoirs situated in the peripheral area of the airport (simultaneously fulfilling the function of detention basins).

All in-ground filtration reservoirs were lined using 2.5 mm thick polyethylene geosynthetic barriers, complying with the strictest quality requirements (the total volume of BAM-certified membranes supplied to BER project was 400 000 m2).